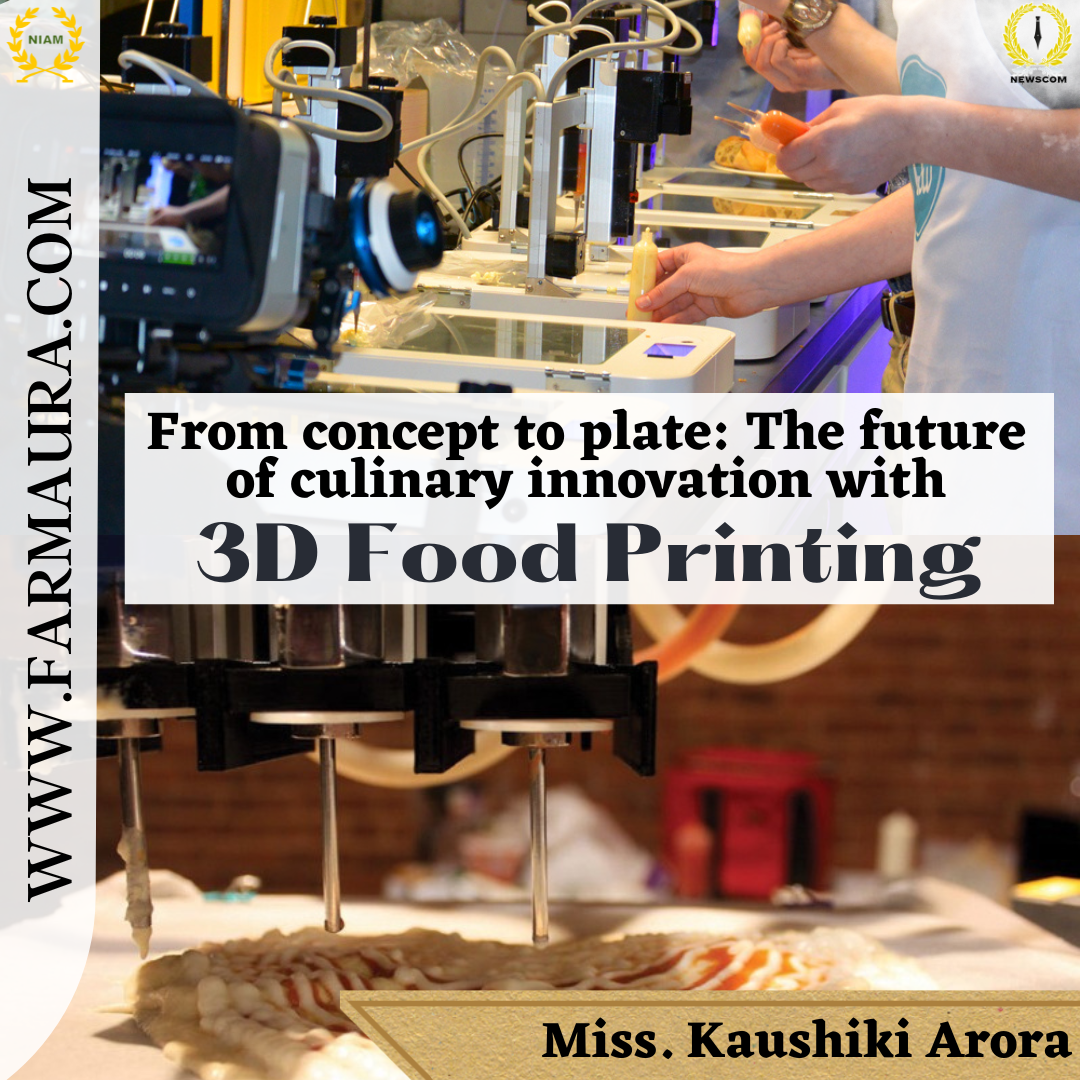

3D food printers employ a variety of additive and subtractive manufacturing processes to produce food products by assembling materials to create objects using 3D model data. Food-grade syringes are most generally used to hold the printing media. It is then deposited layer by layer using a food-grade nozzle. Solid freeform fabrication, or the potential of food material to hold and develop a solid structure without deforming, is the fundamental tenet of 3D printed food.

Collaboration between hardware and software is necessary for 3D printing. The most cutting-edge 3D food printers incorporate easy user interfaces and pre-loaded recipes and designs that are simple to access on a computer, mobile device, or Internet of Things (IoT) device. and allow users to remotely create their meals using computers, smartphones, or other devices. The food’s ability to be altered in terms of shape, colour, texture, flavour, or nutrition makes it extremely helpful in a variety of industries, including healthcare, defense, and space exploration.

The very first multi-material 3D printer called Fab@home was launched in 2006 to print culinary ingredients like chocolate, cookie dough, and cheese, which were developed by a group of Cornell University students. In 2018, a food tech startup called Novameat introduced plant-based meat alternatives. The first meat steak made from plant-based paste inserted into a 3D food printer that mimics the texture of meat was printed using AutoCAD software.

Adopting 3D printing has a unique set of benefits. This revolutionary new technique has the potential to increase food’s nutritional content and perhaps reduce hunger in places where it is difficult to find fresh, affordable foods. It enables meal customization based on preference as it can quantify the precise amount of vitamins, carbs, and fatty acids based on input and establish the appropriate percentage of nutrients for a specific age. It enhances creativity and innovation, as by altering food components, users can create novel dishes. Additionally, it facilitates obtaining perfection with less effort and time.

The adoption of 3D printing technology by the global food sector will increase the productivity and sustainability of food production. It is estimated that the global market for ready-to-eat 3D-printed food will see huge growth from $6,422.5 million in 2019 to $44,520 million by the end of 2026.

However, there are still many challenges as well. Currently, very few ingredients work with food printing. All of the ingredients used in traditional cooking cannot be used in food manufacturing. Every ingredient has specific criteria for cooking and storage, such as an ideal temperature, that ought to be met. Multiple-grade materials can produce textures that are compatible with the necessary sterilisation procedures, giving consumers more food options as well. Because printer prices are currently expensive, the demand for 3D-printed food is unknown. Also, there is a certain level of technical proficiency required to operate the machine, which adds to the overall investment cost.

While some businesses are still researching its technological possibilities, there are key brands like PepsiCo, Hershey, Nestle, Choc Edge, and Barilla that regularly use 3D printing. Oreo has created cookies with specialised crème designs and flavours using 3D printing.

Due to the world’s rapid population growth, there will be an increase in the demand for food, and food sources will become scarce due to wastage. Innovative and competitive technologies, like 3D food printing, are needed to tackle this scenario since they can effectively utilise food resources with little to no waste.

Although 3D printing will continue to advance as a remarkable technology in the food sector, high adoption is most likely to emerge from businesses concentrating on new product development and/or direct-to-consumer business models.